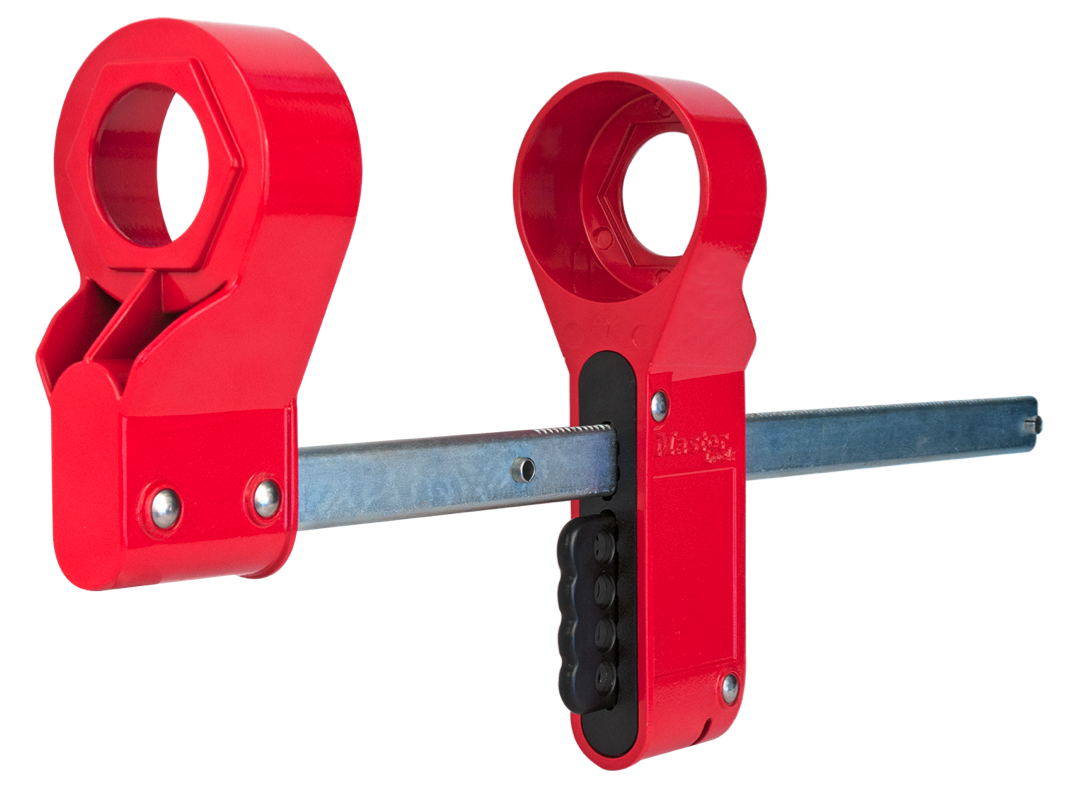

Blind Flange Lockout

Easy to use, adjustable device provides a best-in-class solution for pipeline maintenance.

- Patent Pending

Best practice lockout solution

for pipeline maintenance

- During pipeline maintenance, closed valves upstream could fail or residual material in the line may not be fully drained. These create potential exposure to downstream workers to chemicals, flammable gasses, oil, steam and other risks.

- Use of a blind on a flange pipe is required by OSHA and provides a physical barrier against the unintentional release of energy.

- The new blind flange lockout device provides the best practice solution to improve compliance and control of potential hazards. It ensures the blind will not unintentionally be removed until all work is complete and all personal safety locks are removed.

Blind Flange Lockout

An effective, locked out, physical barrier that helps prevent the removal of the blind until all workers have completed maintenance and remove their personal safety padlock.

Expand to learn more

Three sizes available to cover and lock out nuts ranging from 3/4in (19mm) to 2-3/4in (69.9mm) diameter

Expand to learn more

Adjustable device provides a tight fit, adapting to multiple flanged pipe applications

Expand to learn more

Device fully conceals flange bolts preventing access to the blind until all work has been completed

Expand to learn more

Four locking holes allow for multiple workers to lockout device at one time

Expand to learn more

Durable aluminum and hardened steel construction withstands conditions indoors and out

Video: Blind Flange Lockout best practice pipeline maintenance

Video: Blind Flange Lockout Installation

Print this page Print >

Specifications

|

|

|

|

|---|---|---|---|

| Model Number | S3922 | S3923 | S3924 |

| Description | Blind Lockout Device, Small | Blind Lockout Device, Medium | Blind Lockout Device, Large |

| Recommended Nut Diameter | 3/4in - 1-1/8in (19mm - 28.7mm) |

1in - 1-7/8in (33.3mm - 47.8mm) |

2in - 2-3/4in (52.3mm - 69.9mm) |

| Pipe Diameter Range | 1/2in - 3in (12.7mm - 76.2mm) |

3-1/2in - 12in (88.9mm - 304.8mm) |

14in - 24in (355.6mm - 609.6mm) |

| Pipe Flange Width Range | 1-1/2in - 5-5/8in (38.1mm - 143.3mm) |

3-3/4in - 10-3/4in (95.3mm - 274.6mm) |

7-3/4in - 17-7/8in (196.9mm - 447.8mm) |

| Max Shackle Diameter | 9/32in (7mm) | 9/32in (7mm) | 9/32in (7mm) |

| Material | Powder coated aluminum with hardened steel slide bar | Powder coated aluminum with hardened steel slide bar | Powder coated aluminum with hardened steel slide bar |

| Operating Temperature | -40°F – 200°F (-40°C – 93.3°C) |

-40°F – 200°F (-40°C – 93.3°C) |

-40°F – 200°F (-40°C – 93.3°C) |

| Compliance Testing | REACH, Prop 65 | REACH, Prop 65 | REACH, Prop 65 |

| Individual Packaging | 1 Unit, Commercial Bagged | 1 Unit, Commercial Bagged | 1 Unit, Commercial Bagged |

| Each UPC | 071649274374 | 071649274381 | 071649274398 |

| Master Carton QTY | 6 Units | 6 Units | 6 Units |

| Master Carton UPC | 10071649274371 | 10071649274388 | 10071649274395 |

| List Price | $71.95 | $81.95 | $119.95 |